Energy Storage & Battery Technology

-

Lithium-Ion Battery Anodes: Graphite serves as the dominant anode material in lithium-ion batteries, with natural graphite comprising approximately 52% of usage and synthetic graphite 31% in battery applications. Recent advancements focus on enhancing energy density and reducing charging times for electric vehicles, with companies like Titan Mining developing domestic supply chains for battery-grade graphite.

-

Supercapacitor Technology: Researchers at Monash University have developed graphene-based supercapacitors using a rapid thermal annealing process that creates multiscale reduced graphene oxide (M-rGO). These supercapacitors achieve exceptional performance metrics of 99.5 Wh/L energy density and 69.2 kW/L power density, enabling both high energy storage and rapid power delivery for applications in electrified transportation and grid stabilization.

-

Fuel Cell Components: Synthetic graphite is utilized in bipolar plates for fuel cells due to its excellent conductivity and corrosion resistance. These plates facilitate efficient energy conversion in hydrogen-based power systems, particularly in transportation and stationary power applications.

Industrial Manufacturing & Processing

-

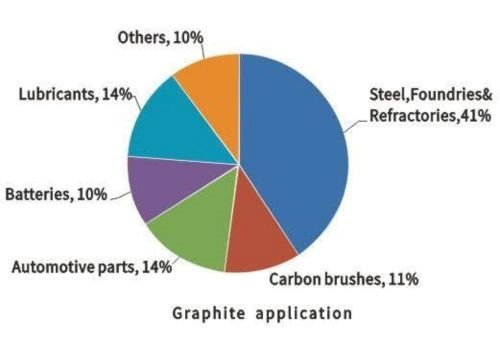

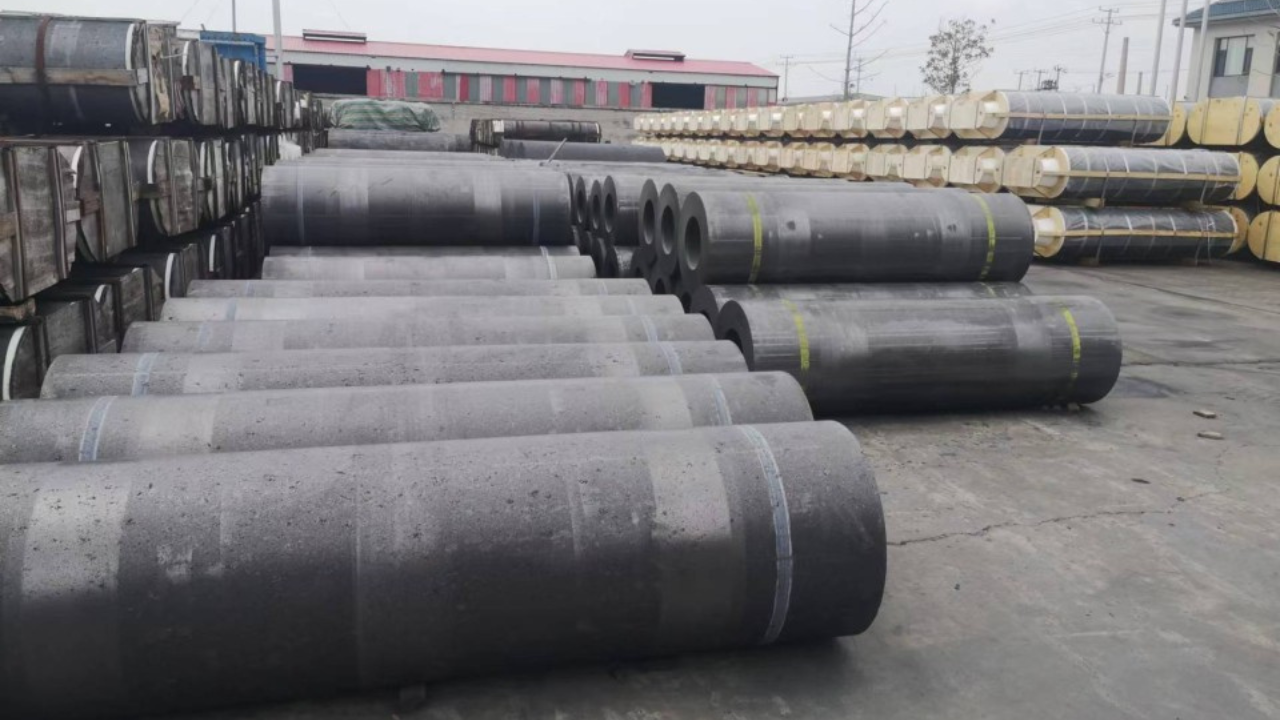

Graphite Electrodes for Electric Arc Furnaces: Synthetic graphite electrodes (comprising 47% of synthetic graphite use) are essential for steel production in electric arc furnaces, where they sustain extremely high temperatures exceeding 3,000°C for melting scrap metal.

-

Refractory Materials: Graphite’s exceptional thermal stability makes it ideal for refractory applications (24% of natural graphite use), including kiln linings, reactors, and industrial furnaces used in ceramic, steel, and power generation industries. Its ability to withstand extreme temperatures while maintaining structural integrity is crucial for these applications.

-

Casting and Mold Applications: Graphite molds are indispensable in continuous casting processes for metals like copper and aluminum, representing approximately 8% of natural graphite use. Their thermal properties, adaptability, and resistance to thermal shock improve manufacturing efficiency and reduce costs.

-

Electrical Discharge Machining (EDM): Graphite electrodes enable precision machining through spark erosion processes, creating complex parts with high accuracy for tooling, aerospace components, and medical devices.

-

Recarburizing Agent: Powdered graphite serves as a carbon additive (2% of natural graphite, 8% of synthetic graphite use) in steel and iron production to achieve optimal carbon content, enhancing final product performance and characteristics.