Table: Graphite Application by Industry Sector and Material Type

| Application Sector | Primary Graphite Type | Key Properties Utilized | Noteworthy Developments |

|---|---|---|---|

| Energy Storage | Natural (52%), Synthetic (31%) | Electrical conductivity, Lithium intercalation | Titan Mining US supply chain |

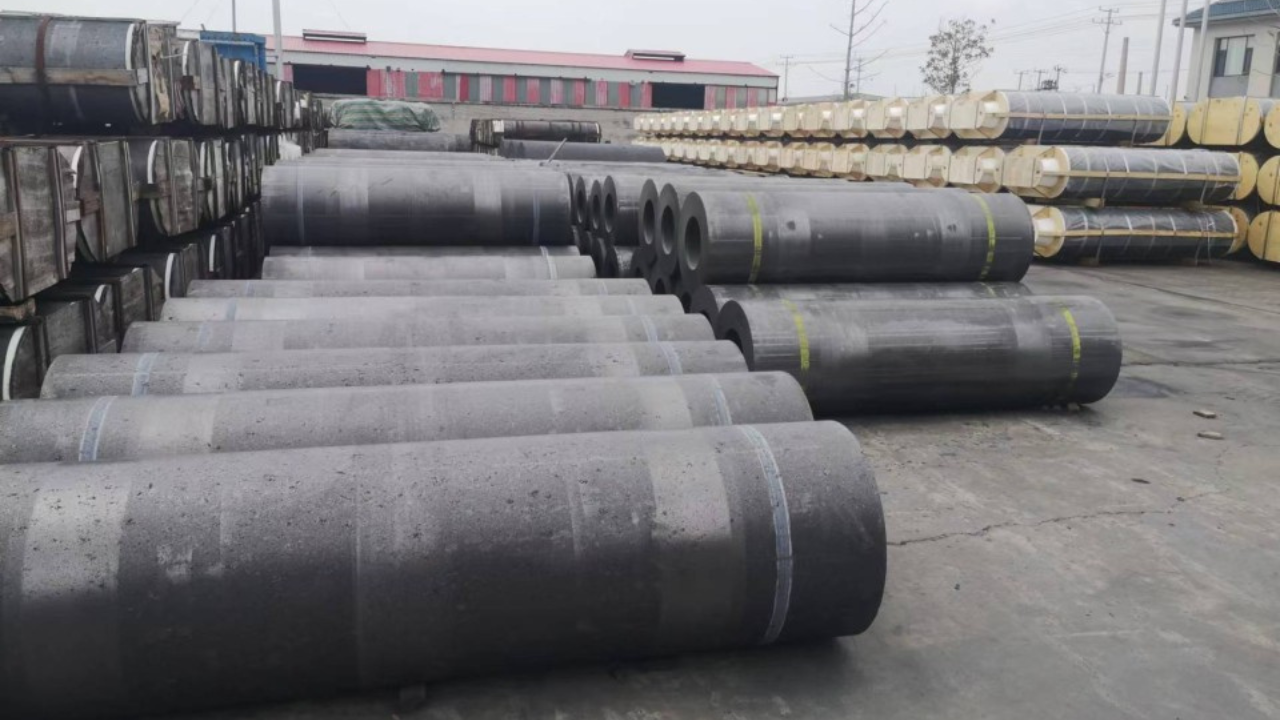

| Industrial Manufacturing | Synthetic (47% for electrodes) | Thermal stability, High temperature resistance | Acheson furnace process optimization |

| Thermal Management | Synthetic graphite, Graphene | Thermal conductivity (>1500 W/m·K) | HydroGraph’s 152% HTC improvement |

| Aerospace & Defense | High-purity synthetic | Temperature resistance, Chemical inertness | Rocket nozzles, UAV components |

| Emerging Technologies | Graphene derivatives | Electrical/thermal conductivity, Flexibility | Monash University supercapacitors |

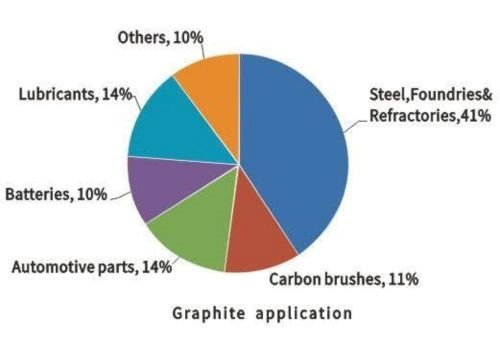

Traditional & Niche Applications

-

Lubricants: Graphite’s layered crystal structure enables its use as a solid lubricant (3% of both natural and synthetic graphite), particularly in high-temperature or dry environments where conventional lubricants would fail.

-

Carbon Brushes and Electrical Contacts: Graphite’s electrical conductivity and self-lubricating properties make it ideal for brushes in electric motors and generators, as well as various electrical contacts and switches.

-

Pencil Production: While representing a smaller percentage of overall use, graphite-clay composites remain essential for pencil manufacturing, leveraging graphite’s ability to leave visible marks on surfaces.

-

Foundry Facings: Graphite powder serves as mold facing in metal casting operations, preventing molten metal from adhering to sand molds and improving surface finish of cast parts.

Future Outlook & Research Directions

Graphite applications continue to evolve with several promising research areas:

-

Radioactive Graphite Repurposing: Investigating using graphite from decommissioned nuclear reactors to generate electricity in “diamond battery” concepts for low-power devices

-

Advanced Thermal Management: Developing enhanced graphene coatings for next-generation electronics cooling, building on recent breakthroughs in heat transfer efficiency

-

Composite Materials: Creating graphite-reinforced composites with improved strength-to-weight ratios for aerospace and automotive applications

-

Medical Applications: Expanding graphene-based implementations in drug delivery, implantable devices, and diagnostic technologies

The global market for specialty graphite continues to grow, projected to reach $2.28 billion by 2031 with a CAGR of 3.2%, driven largely by energy storage and advanced industrial applications. As research continues and production capabilities expand, particularly with new facilities like Titan Mining’s New York operation coming online, graphite’s unique properties ensure it will remain a critical material across multiple industries well into the future.

Table: Global Specialty Graphite Market Projection

| Parameter | 2024 Value | 2031 Projection | CAGR (2025-2031) |

|---|---|---|---|

| Market Size | $1.83 billion | $2.28 billion | 3.2% |

| Regional Leadership | Asia-Pacific (70%) | Asia-Pacific (maintained) | – |

| Leading Application | Photovoltaics | Energy Storage | – |

| Dominant Product Type | Isostatic graphite (75%) | Isostatic graphite (maintained) | – |

For specific technical requirements or application consultations, specialized graphite producers like East Carbon provide material engineering support and custom solutions across these diverse applications.