Application of Metallurgical Coke

The unique properties of metallurgical coke allow it to flourish in many fields, including blast furnace ironmaking, non-ferrous metal smelting, casting, chemical industry, calcium carbide production, and many other fields.

blast furnace ironmaking

In modern blast furnaces, coke simultaneously performs the triple functions of reducing agent, heating agent and material column skeleton, which places extremely high demands on the quality of metallurgical coke.

As a reducing agent, the fixed carbon in metallurgical coke combines with oxygen in iron ore to generate CO and CO2, gradually reducing iron oxides to metallic iron. This process requires the coke to have sufficient carbon content and appropriate reactivity.

As a heat-generating agent, coke combustion provides the high temperature (about 1500°C) required for iron ore melting and slag iron separation, and is required to have a high calorific value (about 29-31 MJ/kg).

As the skeleton of the material column, coke still maintains a certain size in the lower part of the blast furnace to maintain the permeability of the gas channel and the dripping space of the liquid, which places extremely high demands on the hot strength (CSR) of the coke.

Especially in modern large-scale blast furnaces (>4000m3), the smelting intensity is high and the material column pressure is large. The residence time of coke in the blast furnace can reach 20-30 hours, and it undergoes intense mechanical, thermal and chemical reactions. Therefore, the requirements for coke quality are more stringent, usually requiring CSR>65%, CRI<25%, ash content<10%, and sulfur content<0.5%.

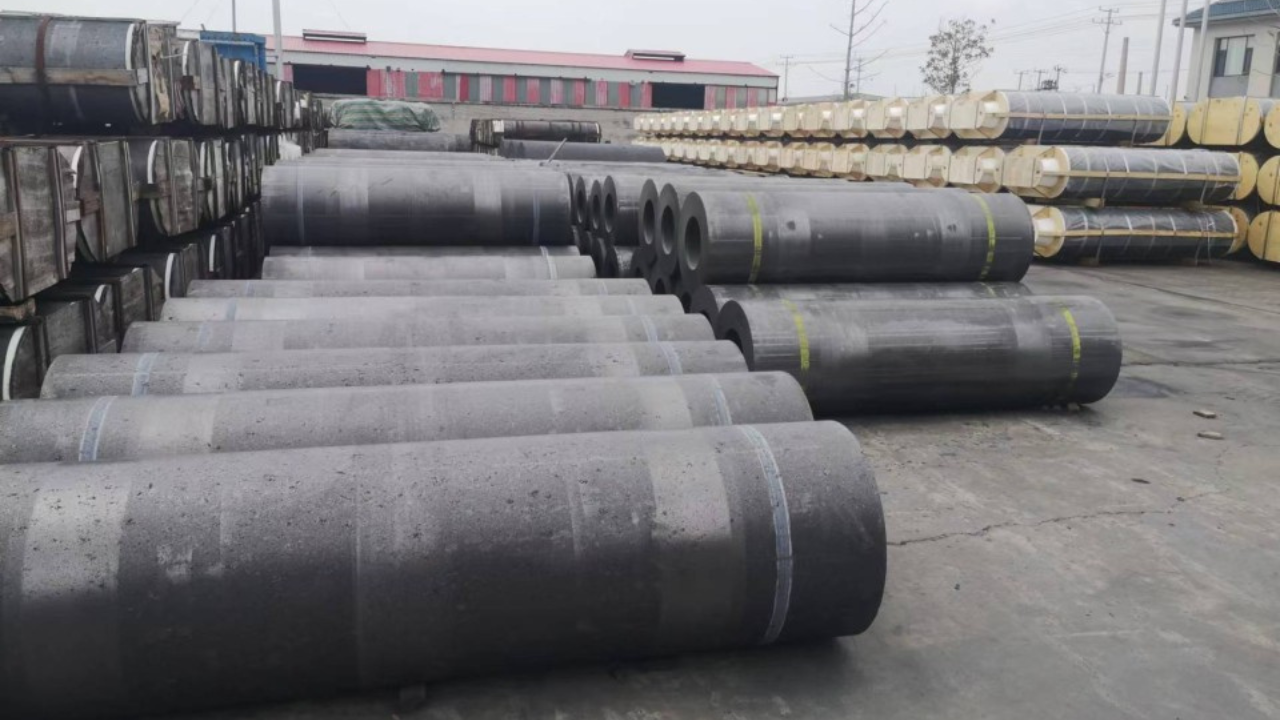

Metallurgical coke participates in blast furnace ironmaking

Foundry Industry

Foundry coke has significantly different performance requirements than other metallurgical cokes:

Foundry coke prioritizes low sulfur (<0.8%), low ash (<10%), and high fixed carbon (>85%) to minimize molten iron contamination.

A larger particle size (generally 60-120mm) is required to enhance furnace air permeability; hot strength requirements are relatively relaxed because cupola temperatures are relatively low (approximately 1350-1400°C) and the mechanical action of the charge is minimal.

High-quality foundry coke is typically produced primarily from low-ash, low-sulfur coking coal and fat coal, which undergoes rigorous screening to remove fines.

With the development of precision casting and high-end equipment manufacturing, demand for specialty foundry coke is growing. For example, large-block coke (>100mm) is used in large castings, and ultra-high fixed carbon (>90%) coke is used in alloy cast iron smelting.

Foundry coke participates in industrial casting