Control the dosage of carburizing agent: The dosage of carburizer

In the steel industry, the effective utilization of scrap steel resources has always been a topic of great concern. With the improvement of environmental awareness and the emphasis on resource recycling, scrap steel casting technology has been widely used in recent years. In the scrap steel casting process, the use of carburizer is a crucial link. This article will discuss how to correctly use carburizers in scrap steel casting production to improve product quality and production efficiency.

The background and significance of scrap steel casting

Scrap steel casting refers to a process that uses scrap steel for recycling casting. Compared with traditional steelmaking production methods, scrap steel casting has the advantages of low energy consumption, short production cycle, and environmental friendliness. Therefore, in the steel industry, scrap steel casting technology is regarded as an important development direction, which helps to realize the recycling of resources and reduce dependence on natural resources.

The role of carburizer in scrap steel casting

Carburizer refers to an additive used to increase the carbon content of molten steel during the casting process. Since the carbon content in scrap steel is usually low, the chemical composition of the molten steel needs to be adjusted by adding carburizers to meet the requirements of cast products. The addition of carburizer can effectively improve the fluidity, lubricity and solidification performance of molten steel, thereby improving the quality and surface finish of the product.

The key to correct use of carburizer

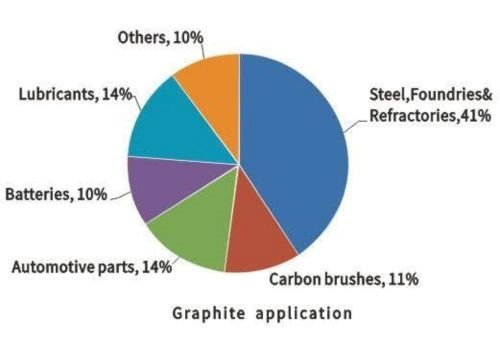

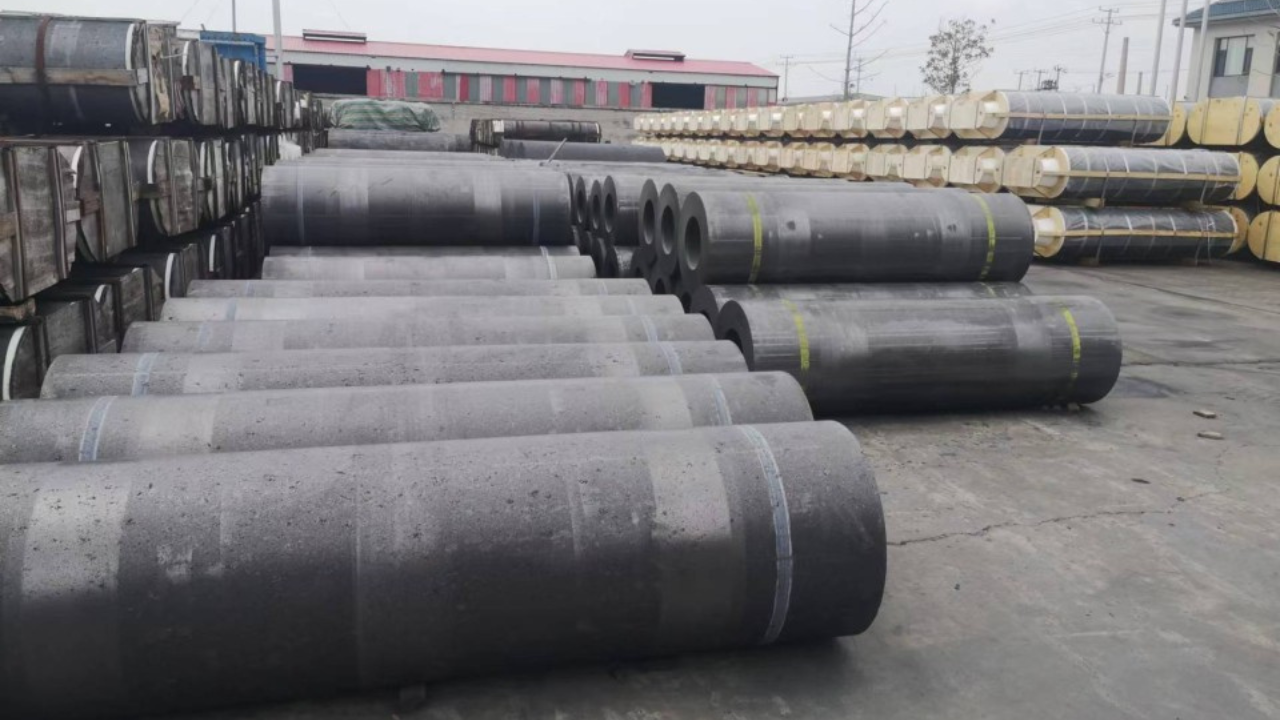

Select the appropriate carburizing agent: During the scrap steel casting process, the appropriate carburizing agent should be selected according to different steel types and production requirements. Common carburizers include natural graphite, artificial graphite, coke, etc. They have different forms and carbon contents, so they need to be selected according to specific circumstances.