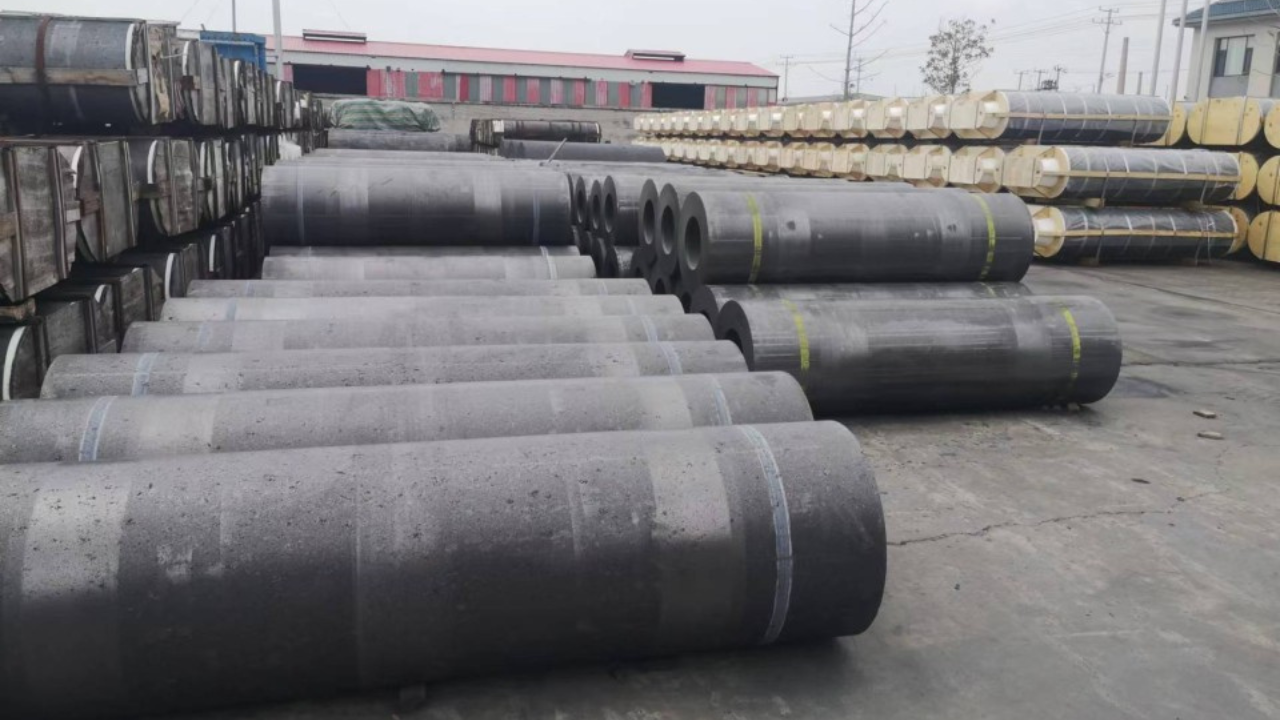

Foundry Coke

North China: Southern Shanxi Province: Linfen and Yuncheng use highly caking coking coal to produce high-end foundry coke with ash content <10% and sulfur content <0.6%, which is supplied to major foundry provinces such as Henan and Shandong (such as the mechanical foundry industry in Changge, Henan and Weifang, Shandong).

Tangshan, Hebei Province: The foundry coke production capacity in Qian’an and Luanzhou areas supports the local cast iron pipe and automobile casting industries, mainly medium-lump coke (60-80mm).

Eastern China: Zaozhuang and Yanzhou, Shandong Province: Relying on gas-fertilizer coal resources, we produce cost-effective foundry coke with uniform size, which is suitable for iron smelting in cupola furnaces and supplied to foundries in Jiangsu and Zhejiang.

Xuzhou, Jiangsu Province: Using coking coal from the Jiawang mining area to produce foundry coke to serve the precision casting industry in the Yangtze River Delta.

Ferroalloy coke

Central and western Inner Mongolia: Ulanqab and Bayannur rely on ferrosilicon and ferromanganese alloy industrial clusters to produce low-ash ferroalloy coke (ash content <12%), using local lignite quality improvement or coking coal resources.

Shizuishan, Ningxia: Relying on Taixi coal (low-ash anthracite) and lignite technology, special ferroalloy coke is produced to meet the needs of high-purity alloy smelting.

Non-ferrous metal smelting coke

Qujing, Yunnan and Panzhihua, Sichuan: Blast furnace smelting of copper, lead and zinc to produce highly reactive coke (reactivity CRI>35%), utilizing local lean coal and poor coal resources.

Xinyu, Jiangxi and Chenzhou, Hunan: To support the local smelting of non-ferrous metals such as tungsten and tin, the coke is mainly small pieces (25-40mm) to meet the air permeability requirements in the furnace.