3. Thermal properties

Including coke reactivity (CRI) and post-reaction strength (CSR). CRI measures the reaction rate of coke with CO2 at 1100℃, characterizing its anti-gasification ability in the lower part of the blast furnace. High-quality metallurgical coke requires a CRI of less than 30%. CSR measures the retention rate of coke in the drum after the reaction, reflecting the structural stability at high temperature. It is usually required to be greater than 60%, and large blast furnaces require higher requirements (>65%).

There is a correlation between these two indicators. Generally speaking, coke with low CRI has higher CSR. They jointly determine the behavior of coke in the soft melting zone and dripping zone of the blast furnace, which is crucial to maintaining the permeability of the material column.

Metallurgical coke reactivity automatic tester

4.Particle size composition

The typical particle size range of metallurgical coke is 25-80mm, of which 40-60mm is the mainstream particle size. We want to know the particle size uniformity, which can be expressed by the uniformity coefficient K (K=(40-80mm)/(>80mm+25-40mm)). The closer the K value is to 1, the better the uniformity. Modern large blast furnaces tend to use medium-sized (around 50mm) and concentrated coke to optimize the balance of gas circulation and reaction kinetics. For particularly large blast furnaces (>4000m3), it is also required to remove the oversized particle size >80mm: to avoid excessive development of central gas flow.

Laser Particle Size Analyzer

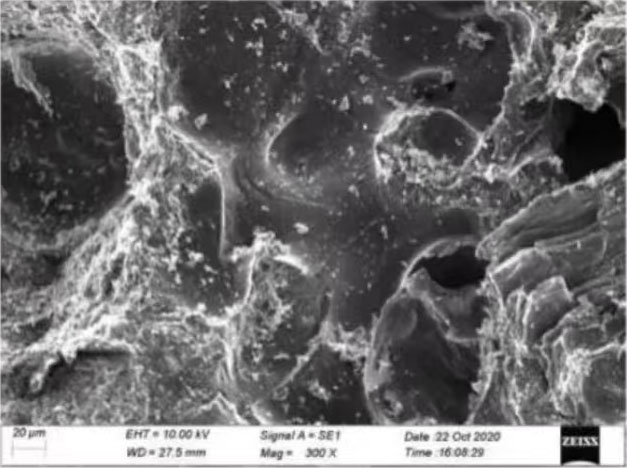

5. Pore structure

High-quality metallurgical coke should have a moderately developed pore system, with a porosity generally between 35% and 55%. Macropores with a pore size >100um are conducive to gas diffusion, while micropores <1um increase the reaction surface area. The ideal pore structure should have good macropore connectivity and not too many micropores, which needs to be achieved by controlling the coal properties and heating system during the coking process.

Metallurgical coke pore structure diagram