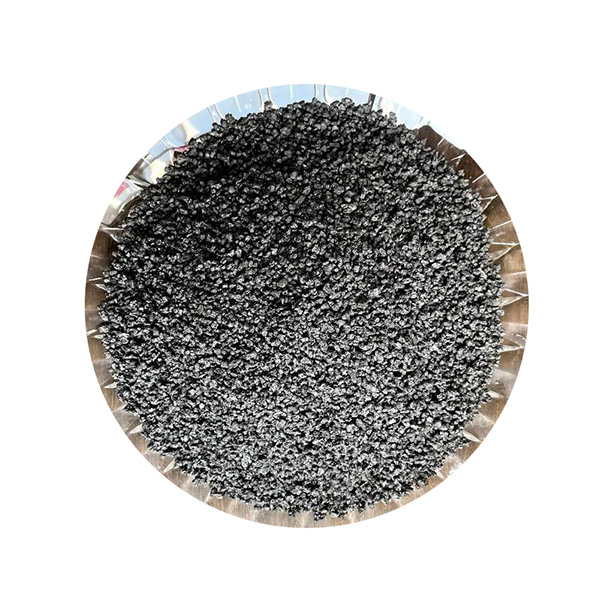

Calcined Anthracite Coal (CAC)

Calcined Anthracite Coal (CAC) Description

Calcined anthracite coal is a form of anthracite coal that has been subjected to high-temperature processing, typically in a rotary kiln or a vertical furnace, to remove volatile components and increase its carbon content. This process makes the coal more suitable for various specialized applications due to its enhanced properties.

Specifications

| Item | Fixed carbon | Sulphur | Ash content | Volatile matter | Moisture |

| CAC-1 | ≥95% | ≤0.25% | ≤4% | ≤1% | ≤0.3% |

| CAC-2 | ≥94% | ≤0.25% | ≤5% | ≤1% | ≤0.3% |

| CAC-3 | ≥93% | ≤0.3% | ≤6% | ≤1.2% | ≤0.5% |

| CAC-4 | ≥92% | ≤0.3% | ≤7% | ≤1.2% | ≤0.5% |

| CAC-5 | ≥90% | ≤0.35% | ≤8% | ≤1.5% | ≤0.5% |

| Size | 0.5-3mm 0.5-4mm 1-3mm 1-4mm 1-5mm 3-5mm 90%minorCustomized | ||||

Application

Steel Production

Calcined anthracite is used as a carbon additive in the production of steel. It serves as a recarburizer, providing carbon content to the molten iron during the steelmaking process.

Ferrous Foundries

It is employed in foundry applications to improve the carbon content of the melt and control the composition of cast iron.

Aluminum Smelting

In some cases, calcined anthracite can be used as a carbon additive in the production of aluminum, similar to its application in steelmaking.

Package

Get Free Quote of Calcined Anthracite Coal (CAC)

Related Products

Related News

Based on appearance and quality, petroleum coke can be divided into three categories: sponge coke, honeycomb coke, and needle coke. […]

Pitch coke is a high-quality coke with a high carbon content, low ash content, and low sulfur content. Its ash […]