The production of metallurgical coke is a complex process, involving seven major links: selection and pretreatment of raw coal, furnace loading, high-temperature carbonization, coke oven heating, pushing and quenching, screening and chemical recovery of whole particles.

Production of metallurgical coke

-

Raw material preparation

Qualified coking coal materials need to meet the requirements of precise proportion, appropriate particle size and uniform moisture.

The coal preparation process usually includes steps such as unloading, storage and mixing, blending, crushing and mixing.

According to the different coal quality characteristics, there are three mainstream coal preparation processes:

- Mixed crushing process (various coals are first blended and then crushed)

- Separate crushing process (various coals are first crushed and then blended)

- Selective crushing process (separate treatment according to particle size classification).

Among them, the selective crushing process can carry out targeted treatment according to the differences in the petrographic composition of coal, avoiding excessive crushing of components with good adhesion. It is a more advanced coal preparation technology, especially suitable for raw materials with uneven coal quality or containing more inert components. The particle size of coal is usually controlled to be less than 3mm, accounting for 75%-85%. Too fine will reduce the strength of coke, and too coarse will affect the bonding.

A common coal preparation process

-

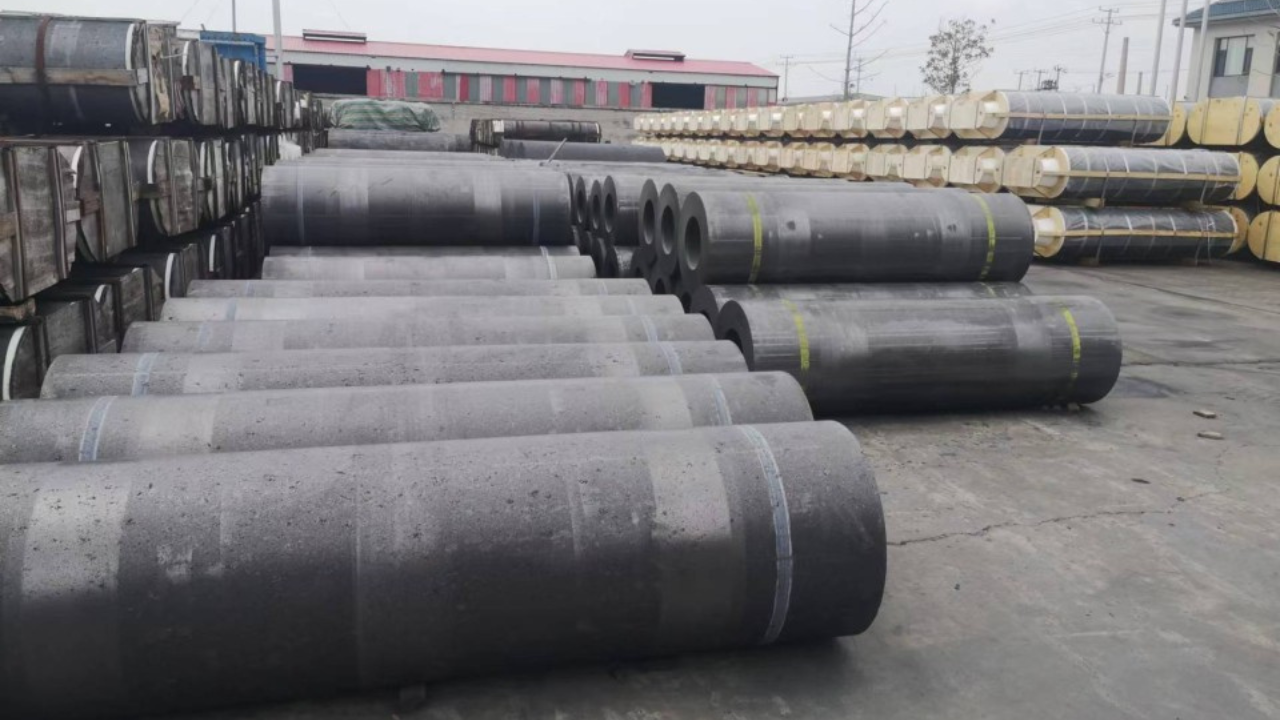

Furnace charging

The prepared coal is loaded from the coal tower into the coke oven carbonization chamber. The carbonization chamber of a modern large coke oven can reach a height of 7-8 meters, with an effective volume of more than 50m3, and a single hole coal loading capacity of more than 40 tons.

When charging the furnace, the distribution of coal is required to be uniform and the density of coal is moderate, which directly affects the uniformity of coke quality and the production efficiency of the coke oven.

The raw coal gas generated during the coal loading process is immediately introduced into the gas collection system and sent to the chemical production workshop for purification. The technological progress at this stage is mainly reflected in the sealing performance and automation level of the coal loading car. Modern coal loading cars use steam injection or high-pressure ammonia technology to control smoke emissions, which significantly improves the working environment.

Coal tower

-

High-temperature carbonization

The coal is heated to 950-1100℃ under air-tight conditions, and undergoes drying, pyrolysis, melting, solidification, shrinkage and other stages to finally form coke.

This process usually takes 14-18 hours (depending on the width of the carbonization chamber and the heating system). This process can be more specifically divided into several key temperature zones:

- In the 350-480°C range, the large structure of the coal decomposes dramatically to form a colloid with coexisting phases. The characteristics of the colloid at this stage (quantity, fluidity and thermal stability) determine the bonding quality of the coke.

- In the 450-550°C range, the liquid phase product further decomposes and condenses to form semi-coke.

- At 700-1000℃, the semi-coke completes aromatization and shrinks to form the final coke.

The entire carbonization process requires precise control of the heating rate and temperature distribution to avoid excessive thermal stress leading to increased cracks in the coke.

Coke oven carbonization chamber