Material Overview and Market Significance

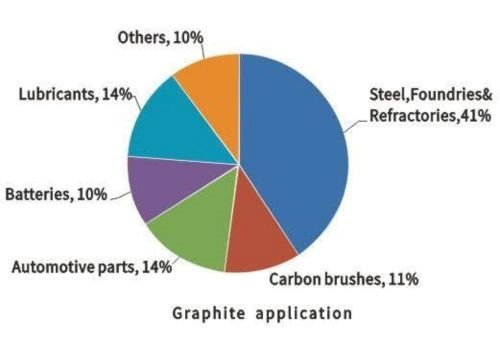

Synthetic graphite represents a critically engineered material with projected market valuation exceeding $9.2 billion, driven by its exceptional properties and diverse industrial applications. Unlike natural graphite, this human-engineered carbon material undergoes precise manufacturing processes to achieve tailored characteristics for specific performance requirements across multiple sectors including energy storage, electronics, and metallurgy.

Fundamental Characteristics and Properties

Exceptional Thermal Management

Synthetic graphite exhibits superior thermal conductivity (400-1500 W/m·K depending on grade), enabling efficient heat dissipation in high-temperature applications such as:

-

Thermal management systems for electronic devices

-

High-temperature furnace components (operating to 3000°C in inert atmospheres)

-

Heat exchanger elements in extreme environments

Electrical Performance

The material demonstrates excellent electrical conductivity (3-5 × 10⁵ S/m) due to its highly ordered crystalline structure, making it indispensable for:

-

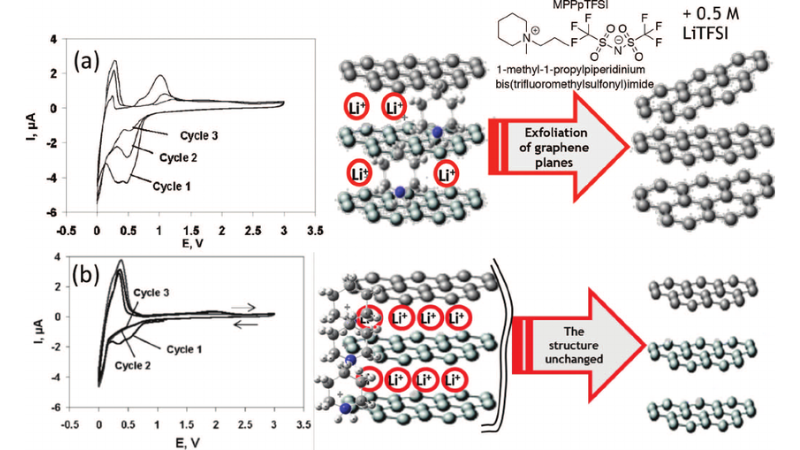

Battery anode materials in lithium-ion systems

-

Electrochemical processing electrodes

-

Conductive composites for electromagnetic shielding

Chemical and Mechanical Properties

-

Outstanding chemical inertness: Resists corrosion from most acids, alkalis, and organic solvents

-

Self-lubricating characteristics: Coefficient of friction 0.1-0.2 in atmospheric conditions

-

High thermal shock resistance: Withstands rapid temperature changes exceeding 2000°C/min

Manufacturing Process: Precision Engineering

Raw Material Selection and Preparation

The production begins with high-purity carbon precursors:

-

Needle coke (primary feedstock): Provides preferred crystalline orientation

-

Coal tar pitch: Serves as binding agent

-

Secondary graphite: Recycled material for cost-effective grades

Quality control measures ensure carbon content >99.95% for premium grades, with sulfur and metal impurities maintained at <50 ppm.

Thermal Processing Stages

-

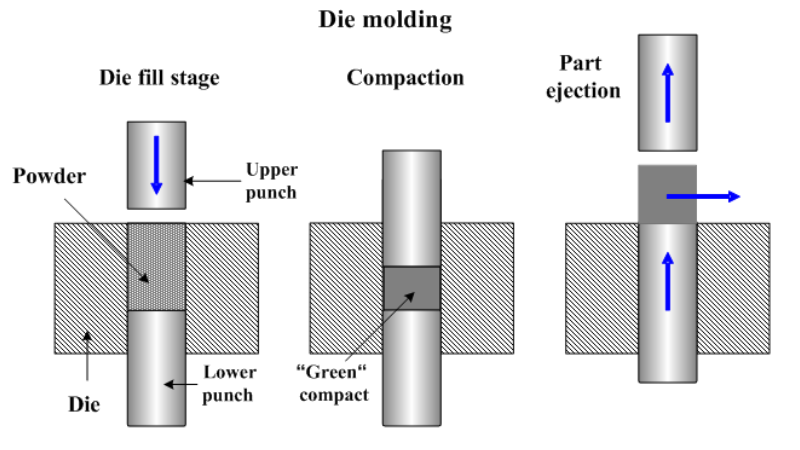

Forming and Baking

-

Isostatic pressing at 100-200 MPa for isotropic properties

-

Extrusion for anisotropic structures

-

Initial baking at 800-1000°C to develop initial carbon structure

-

-

High-Temperature Graphitization

-

Acheson furnace treatment at 2500-3000°C

-

Induction heating for premium grades

-

Crystalline reorganization achieving d-spacing of 3.354 Å

-

-

Purification and Finishing

-

Halogen purification for 99.999%+ purity

-

Mechanical processing to achieve specific particle size distributions

-

Surface treatments for enhanced compatibility

-

Material Classification and Grades

Primary Synthetic Graphite

-

Production: Virgin carbon materials through complete graphitization

-

Characteristics:

-

Isotropic/anisotropic structures

-

Ultra-high purity (99.99%+ carbon)

-

Superior mechanical properties

-

-

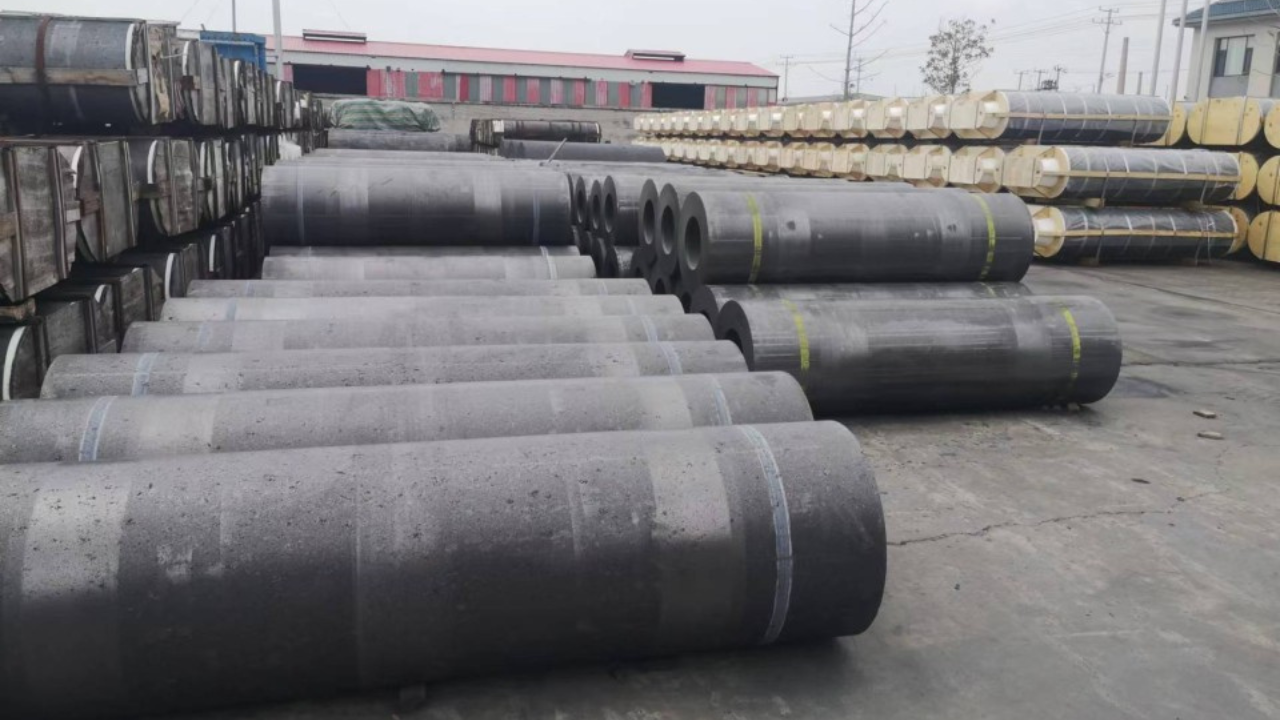

Applications: Nuclear reactors, semiconductor manufacturing, aerospace components

Secondary Synthetic Graphite

-

Production: Recycled graphite products and manufacturing scrap

-

Characteristics:

-

Cost-effective alternative

-

Slightly reduced properties

-

30-40% lower environmental impact

-

-

Applications: Foundry facings, lubricants, conductive paints