Economic Considerations and Market Dynamics

Pricing Structure

| Grade Type | Price Range (USD/ton) | Key Applications |

|---|---|---|

| Standard Industrial | 2,000-5,000 | Lubricants, refractories |

| Battery Grade | 8,000-12,000 | Li-ion anodes |

| Ultra-High Purity | 15,000-20,000 | Semiconductor, nuclear |

| Specialty Forms | 20,000-30,000 | Aerospace, defense |

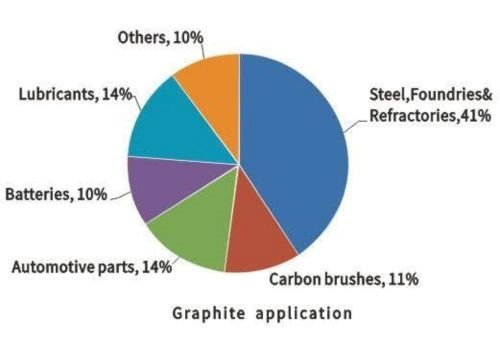

Market Drivers

-

Electric vehicle expansion: 65% of synthetic graphite demand growth

-

Energy storage systems: Grid storage applications increasing 25% annually

-

Electronics miniaturization: Thermal management requirements

-

Green technology: Hydrogen fuel cells and renewable energy systems

Advanced Applications and Implementation

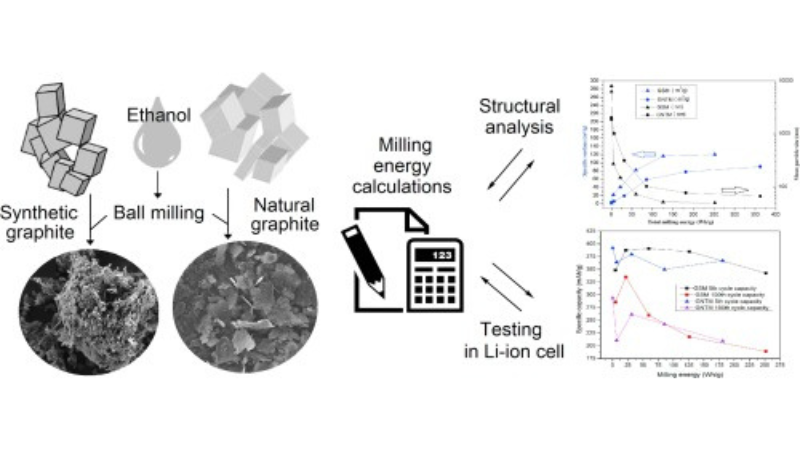

Energy Storage Systems

-

Lithium-ion battery anodes:

-

Capacity: 330-360 mAh/g

-

Cycle life: >1000 cycles at 80% capacity retention

-

Efficiency: >99.5% Coulombic efficiency

-

-

Fuel cell components:

-

Bipolar plates with <10 mΩ·cm² resistivity

-

Chemical stability in acidic/alkaline environments

-

Industrial Processing

-

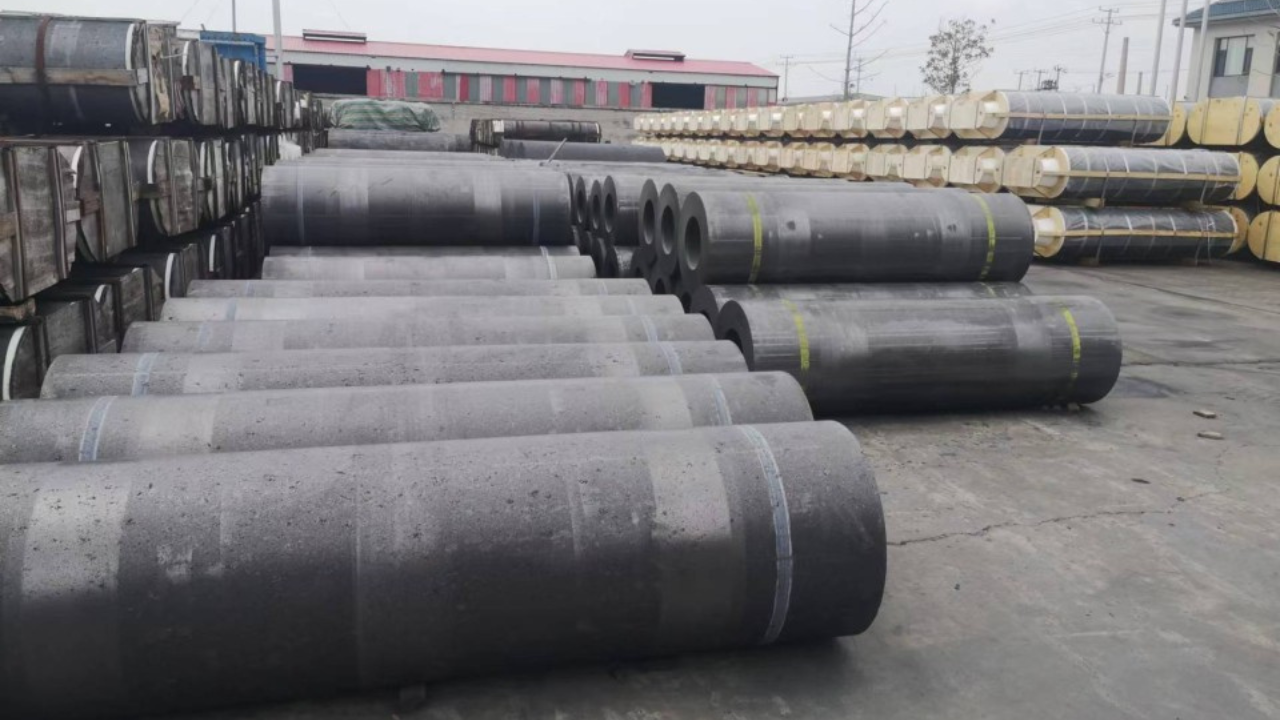

Metallurgical applications:

-

Graphite electrodes for EAF steelmaking (consumption 1.2-2.0 kg/ton steel)

-

Continuous casting dies and molds

-

-

Electrochemical processes:

-

Aluminum production cathodes

-

Chlor-alkali process electrodes

-

Advanced Composites

-

Polymer composites: 20-30% weight reduction with enhanced conductivity

-

Thermal management systems: Heat spreaders with 500-800 W/m·K conductivity

-

Structural components: High-temperature fixtures and tooling

Quality Standards and Certification

International Specifications

-

ISO 80000 series: Material properties and testing methods

-

UL 94 V-0: Flammability resistance

-

RoHS/REACH compliance: Restricted substance management

Industry-Specific Certifications

-

Automotive: IATF 16949 for battery materials

-

Aerospace: AS9100 for structural components

-

Medical: ISO 13485 for implantable devices

Technical Comparison: Natural vs. Synthetic Graphite

| Parameter | Synthetic Graphite | Natural Graphite |

|---|---|---|

| Purity (%) | 99.95-99.999 | 94-99 |

| Crystallinity | Highly ordered | Variable |

| Consistency | Excellent | Moderate |

| Cost Factor | 1.5-3.0× | 1.0× |

| Battery Performance | Superior cycle life | Higher capacity |

Future Outlook and Development Trends

Material Innovations

-

Nano-engineered graphite: Enhanced ionic conductivity for fast-charging batteries

-

Composite structures: Graphene-enhanced synthetic graphite

-

Functionalized surfaces: Improved compatibility with polymer matrices

Sustainability Initiatives

-

Closed-loop recycling: 95% material recovery efficiency

-

Energy-efficient production: 30% reduction in graphitization energy requirements

-

Carbon footprint reduction: Lifecycle assessment implementation

Emerging Applications

-

Quantum computing components: High-purity graphite for qubit support structures

-

Space technology: Thermal protection systems for re-entry vehicles

-

Advanced nuclear systems: Moderator and reflector materials

Selection Considerations and Technical Support

Material Selection Guidelines

-

Purity requirements: Based on application criticality

-

Structural needs: Isotropic vs. anisotropic properties

-

Economic factors: Total cost of ownership calculations

-

Regulatory compliance: Industry-specific requirements

Technical Partnership Benefits

Companies like East Carbon provide:

-

Application engineering support

-

Custom material development

-

Quality assurance programs

-

Global supply chain management

This comprehensive technical overview demonstrates why synthetic graphite remains an indispensable engineering material across multiple high-technology sectors, with continued innovation driving performance improvements and expanding application possibilities.